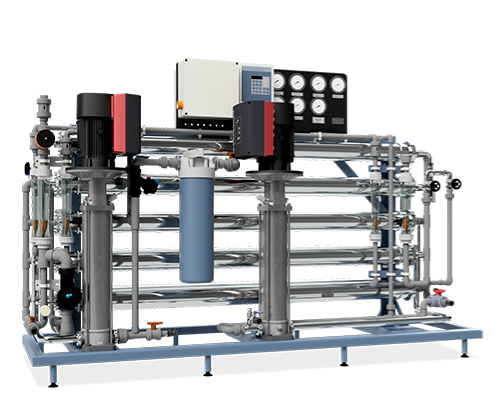

Double-pass RO

Reverse Osmosis can remove more than 98% of the dissolved salts, particles, organics, bacteria, and pyrogens from the feedwater.

Double-pass RO can supply water qualities with conductivities below 2 µS/cm by treating the permeate water from the first RO in a second RO. It also functions as a hygienic barrier against penetration of germs and bacteria in accordance with the US pharmacopoeia.

Features

- Energy-efficient E-pumps

- Low-energy membranes

- No use of chemicals

- High-quality components

- Minimal maintenance

Product overview

Our product range comprises a number of pre-engineered double-pass RO plants with a flow rate up to 3.2 m3/h. The starting point is our modular-built standard system ensuring high flexibility, high reliability in operation, and short delivery time. All plants consist of selected high-quality components and intelligent features, e.g. Grundfos E-pumps that help reduce energy.

Each solution can be customized and built according to the specific application by adapting the choice of material, instrumentation, and control system - based on our combined know-how.

Contact your local sales and service office for more information and request of data sheets and instructions.

Flow up to 1.08 m3/h

| Pressure vessel: | Stainless steel |

| Pipe system: | PVC |

| Membranes: | 4" |

| Product type: | DPRO B1 |

Flow up to 3.2 m3/h

| Pressure vessel: | Stainless steel |

| Pipe system: | PVC |

| Membranes: | 4" |

| Product type: | DPRO B2 |

Customized

Flow rate up to 25 m3/h

Pressure vessel: Steel coated with polyethylene

Membranes: 8"

Type: DPRO C4

With a customized double-pass reverse osmosis plant, it is possible to attain a flow rate up to 25 m3/h. The plant is engineered according to the same design principles as our standard plants but customized to fit your specific needs.

The picture shows 3 x DPRO C4 providing demineralized water with low conductivity for Combined Cycle Gas Turbines.

Selected references using double-pass RO

Purified water for sterilization

Complete water treatment plant for the supply of demineralized water to the washer disinfectors and steam autoclaves. The solution consists of two independent double-pass reverse osmosis (DPRO) units to secure the production of demineralized water in case of breakdown or preventive maintenance.

Chemical-free make-up water for power plant

Energie Steiermark Power Plant in Graz has replaced their existing water treatment plant for producing make-up water. One of their main concerns was to avoid the use of chemicals. By using a double pass RO, membrane degasser and EDI, ultrapure water of a very high quality is produced.

Reverse osmosis unit in stainless steel

The standards for ingredient water are extremely high when used in cosmetics. A double pass RO in stainless steel AISI 316L for a sanitary design reduce microbiological growth. This plant was designed and produced for one of the biggest cosmetic manufacturers in the beauty industry worldwide.

Let's talk water

Selection of unit depends on application, water quality, and water consumption. We are at your service to ensure the optimum solution based on our combined know-how.