Softening units for removal of hardness

The softening units are used for reduction of calcium and magnesium in the water using a cation exchanger. Calcium and magnesium are exchanged for sodium through ion exchange.

Softened water is used for steam boiler plants, district heating plants, laundries, cooling towers, rinse processes, washing, dishwashing etc.

Why water softening?

Softening prevents calcium deposits in e.g. piping, steam boilers, district heating installations, hot water units, heat exchangers, and cooling towers. Traditional use of chemicals for calcium binding can be avoided. In other words, softening can optimize energy use in boilers and hot-water units, minimize chemical usage and prolong the life of installations and plants.

Application of softening units

Water softening before reverse osmosis

Formation of scale can be damaging to the membranes in a reverse osmosis plant. Having a softening unit before your reverse osmosis plant will prolong the life span of the plant and obtain operational reliability.

Softening of drinking water

Groundwater can contain high amounts of calcium and magnesium. For water utilities, it can be relevant to use water softening to prevent scale formation in pipe systems and plumbing.

Softened process water

Softening of water used for rinsing, cleaning, cooling etc. is a valuable investment to avoid the issues which hard water can cause on equipment. And it can also be an environmentally friendly solution. For example in commercial laundries where soft water makes it possible to lower the wash temperatures and hereby reduce the use of detergent.

See reference from a commercial laundry

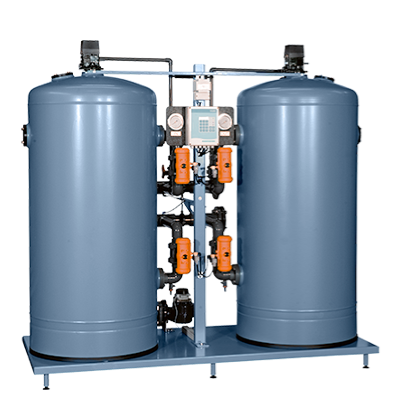

Designed for maximum reliability

The softening plant type SMP is specifically designed for applications which demand high reliability of operation. The construction of the plant and the pipe system result in a low pressure loss and consequently less energy consumption.

The SMP is available in Simplex, Duplex and Triplex versions. The plants are equipped with automatic, pneumatically actuated ball valves – if supply of electricity and air is not available, the valves are closed.

Download leaflet to read more about the features of the softening plant SMP.

Anti-corrosion tanks

The filter tanks are of steel and therefore less susceptible to changes in pressure. The tanks are coated with polyethylene. Thus, the filter tanks combine the strength of steel with the strong anticorrosion property of synthetic material.

Fail-safe valve

Our patented five-cycle valve is made of high-quality synthetic material and has few movable parts. Taken together, this endows the valve with reliable operation, long life and minimum maintenance.

Pipe system

As standard, the pipe system is supplied as PVC or PP with the quality of being corrosion-proof and resistant to chemicals. The pipe system can also be customized in several other plastic types or stainless steel. Steel is a robust material that endures very high temperatures.

Standard control

Each softening plant comes with a standard PLC control. Our controls are purpose-made and individually programmed by our own engineers. The simple user interface facilitates check of configuration parameters and control of operation and regeneration.

Product overview

Our product range comprises a wide number of standard plants, all engineered and manufactured in-house. The starting point is our modular-built standard system ensuring high flexibility, high reliability in operation, and short delivery time. Each solution can be customized and built according to the specific application by adapting the choice of material, instrumentation, and control system - based on our combined know-how.

Plant design

Standard plants are available as one-tank or two-tank units for continuous water production. Each tank has individual valves to ensure reliable operation. All plant types come with a brine tank.

Several of the plant types are available for treatment of both cold (max. 35 oC) and hot water (max. 85 oC). The plants for hot-water softening is especially suited for sanitary installations.

Contact your local sales and service office for more information, data sheets or instructions.

Flow up to 4.1 m3/h

| Product type: | SM / SG |

| Temperature: | Cold or hot |

| Pipe system: | PVC or stainless steel AISI 316L |

| Brine maker: | No |

Flow up to 30 m3/h

| Product type: | SMPG |

| Temperature: | Hot |

| Pipe system: | Stainless steel AISI 316L |

| Brine maker: | Option |

Flow up to 60 m3/h

| Product type: | SMH / SMP |

| Temperature: | Cold |

| Pipe system: | PVC or PP |

| Brine maker: | Option |

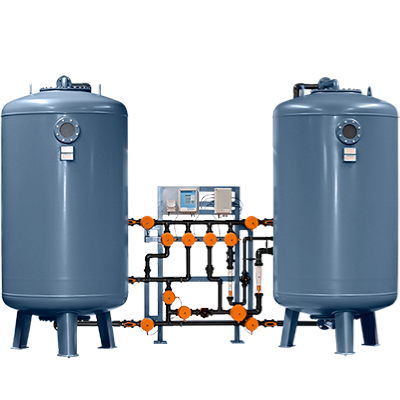

Flow up to 140 m3/h

| Product type: | STFA |

| Temperature: | Cold |

| Pipe system: | PVC or PP |

| Brine maker: | Yes |

Options - for a reliable production

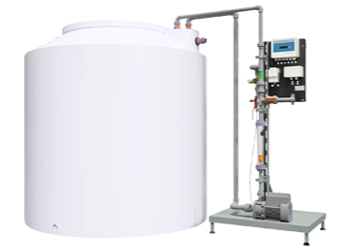

Brine maker

A brine maker is an automatic system for production of large quantities of brine. Typically, fewer salt fillings are needed. At the same time, an inexpensive salt type can be used. It is possible to choose a brine maker for several of the plant series.

Automatic quality test

The quality of the softened water can be monitored by a Online Hardness Control analyzing the residual hardness in the water. The Online Hardness Control is set to an actual hardness limit. Exceeding this limit will release an alarm and start a regeneration.

Manual test kit

Monitoring of softened water can also be done manually with our Durognost test kit. An easy and quick solution for testing the residual hardness after softening.

Efficient water and salt-saving softening

Regenerating the softening plant accounts for a significant portion of operating costs. To minimise water and salt usage, additional features can monitor regeneration water quality, reuse water from different regeneration phases, and optimise salt usage based on ambient temperature.

Focusing on operational safety and economy one of the largest hospitals in Denmark has installed a STFA softening unit for different wash zones.

Type: STFA 30 duplex

Pipe material: PVC

Temperature: 10 °C

Flow: 50 m3/h

Hot water softening

In manufacturing processes, consistency is key to producing high-quality products and keep operational reliability.

A German manufacture of freeze-dried coffee has installed a EUROWATER solution for hot water softening. The treated water is condensate return water for steam boiler.

Type: SMPG

Tank and pipe system: AISI316L

Temperature: 85 °C

Flow: 4 m3/h

Salt tablets for water softening

The quality of the salt used for regeneration can influence the performance of your softening unit. EUROWATER salt tablets are produced under controlled production conditions and are tested in our own plants. Our product is approved for food processing applications and contains typically 99.8% of sodium chloride (min. 99%).

For more information download our leaflet about high-quality salt from EUROWATER.

10 kg

Plactic bag with handle

25 kg

Plastic bag

1000 kg

A pallet with 40 bags

Get the optimum softening solution

Read more about softening and our softening units in this leaflet, where we have collected all about reliable softeners.

Rental of water softening plant

Do you need softened water for a short period of time?

Rent a mobile water treatment plant (skid mounted) from EUROWATER.

Get the optimum solution

Selection of unit depends on application, water quality, and water consumption. We are at your service to ensure the optimum solution based on our combined know-how. Fill in the form and let us get back to you.