Vacuum deaerator

Vacuum deaerators remove dissolved gases including oxygen, nitrogen and carbon dioxide.

The risk of corrosion, scaling and plugging of piping in the district heating systems can be minimized significantly by reducing the content of oxygen and CO2 in the water.

For every m3 of untreated make-up water, 10-15 g of iron will be converted by corrosion. Untreated make-up water contains 8-10 mg/l of oxygen but with a vacuum deaerator, the oxygen content can be reduced to less than 0.2 mg/l.

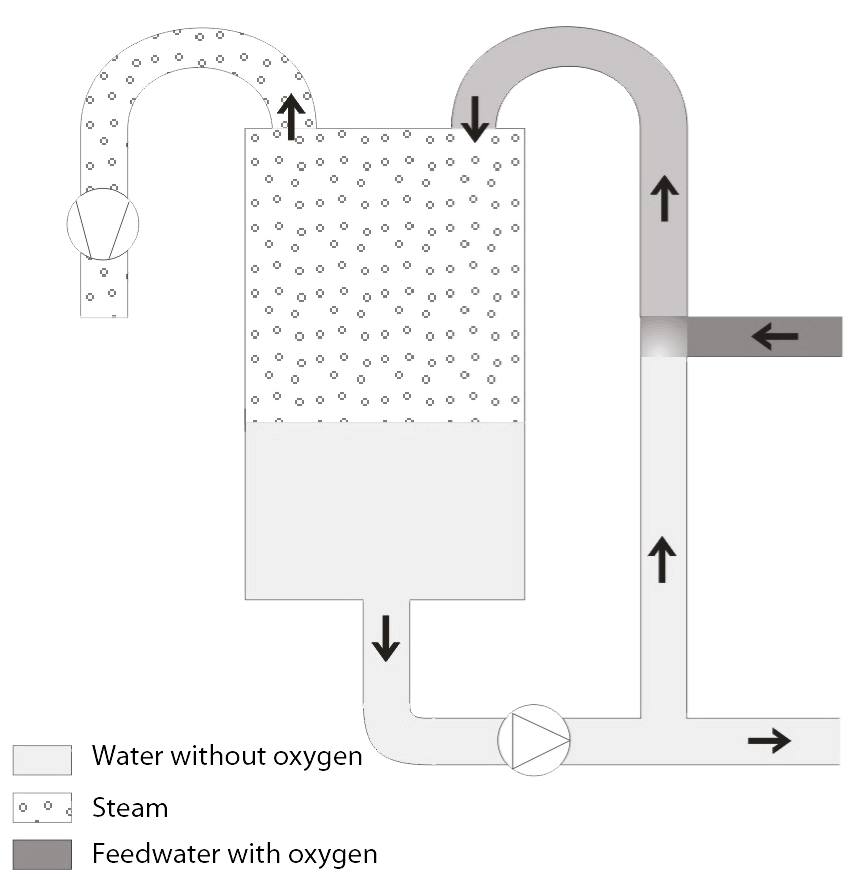

Function of vacuum deaerator

The oxygen-containing make-up water, preheated to 40-90 °C, is conducted to the upper section of the deaeration tank. In order to optimize the removal of oxygen, the deaeration tank is equipped with fillers for division of the water into fine particles.

The vacuum pump creates the necessary vacuum so that the make-up water boils. When the water boils, the oxygen is liberated and removed by means of the vacuum pump. The deaerated water is separated into two streams, which are pumped partly into the district heating network, partly recycled over the deaeration tank.

Stainless steel

Vacuum deaerator is available in corrosion-resistant stainless steel AISI 304.

The photo shows a vacuum deaerator of stainless steel for removal of oxygen from make-up water. The customer is one of the largest public companies in Poland dealing with extraction and distribution of natural resources.

Recommendation

Insulate to prevent heat loss

Insulation of the vacuum deaerator, and in general all installations in contact with hot water, can prevent the condensation of steam and loss of heat.

Reliable design

EUROWATER vacuum deaerators are manufactured of both galvanized and stainless steel and available in 6 modules with flow rates up to 22 m3/h.

All components are selected and designed for maximum reliability and low maintenance. The vacuum deaerator consists of three main components.

For more information and data sheets, please contact your local EUROWATER sales office.

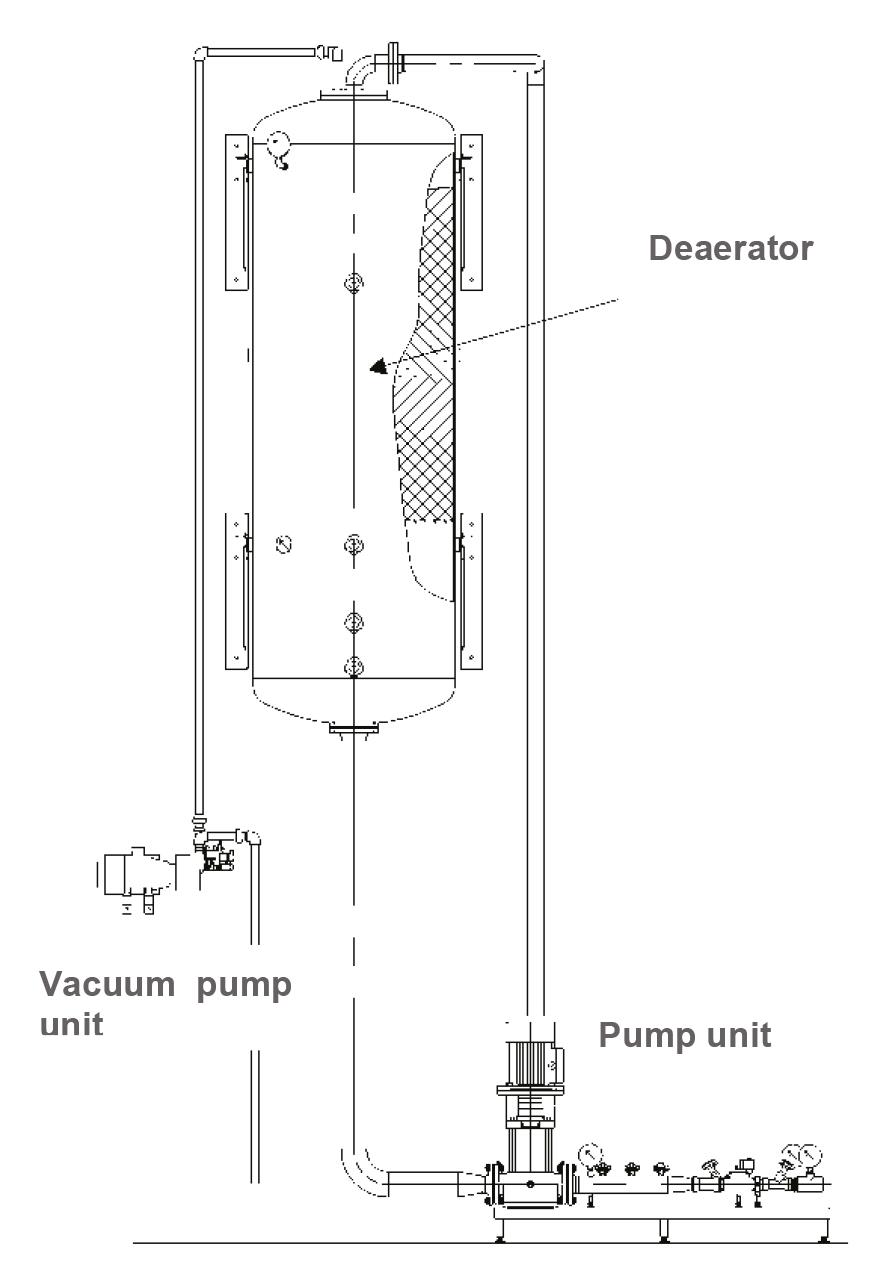

1. Deaeration tank

The deaeration tank is of galvanized or stainless steel. Inside, the tank is equipped with an intermediate bottom, under which a reservoir for deaerated water is installed. Fillers are installed on top of the intermediate bottom. The plant is provided with switches for level control and is delivered with bracket for wall-mounting.

2. Vacuum pump unit

The vacuum pump unit consists of a vacuum pump (liquid ring pump) as well as a valve arrangement for setting of cooling water quantity and vacuum force. The vacuum pump is delivered on a bracket for wall-mounting.

3. Pump unit

The pump unit consists of a centrifugal pump and of a pipe system with valves for setting of the make-up water quantity and the circulating quantity. The pipe system is available in galvanized or stainless steel, and the pump of stainless steel.

All-in-one vacuum deaerator

The vacuum deaerator is also available as a compact unit with tank, control unit, heat exchanger, vacuum pump unit, and cooling water system - all on one frame. Easy, space-saving and simple installation. The flow rate is 1 m3/h.

Get the optimum solution

Selection of unit depends on application, water quality, and water consumption. We are at your service to ensure the optimum solution based on our combined know-how. Fill in the form and let us get back to you.