Maintain the bath quality with good water quality

The pretreatment system performs cleaning, rinsing and preparation of the product surface. The purpose of a pretreatment system is to ensure corrosion protection, optimal coating adhesion, superior optics, and durable surfaces. All these factors depend on proper rinse water quality for achieving excellent product finish.

Demineralized make-up water

In all water-based pretreatment systems there is a need to add fresh make-up water due to evaporation, drag-over, renewal of the water in the different baths, etc. If available, the distillate from a vacuum distillation system can serve as a feedwater source.

The requirement for the make-up water is demineralized water with low salt and silica content. But to keep a continuous, smooth system operation it is essential to treat the inlet water. The purpose of pretreatment is to prevent clogging of the membranes with precipitations and suspended solids and to remove free chlorine

Treatment for optimal make-up water

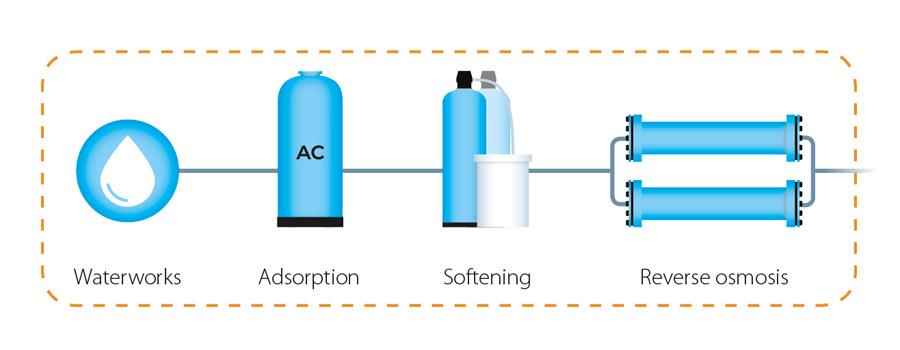

- Inlet water treatment

Adsorption by pressure filter or activated carbon filter for the removal of precipitation, suspended solids and free chlorine. - Removal of hardness

Softening for hardness removal to prevent membrane scaling - 99% removal of inorganic materials and microorganisms

Reverse osmosis (RO) unit producing demineralized water with a conductivity between 10 and 15 μS/cm.

Recirculating rinse water

Recirculation over ion exchange resin reduces the amount of fresh make-up water needed. This is a sustainable solution to lower water consumption and even reduce cost.

Water for reuse is treated in several steps:

- Filtration of mechanical impurities

- Adsorption of organic substances

- Demineralization with ion exchange

Important factors to consider for recirculation systems

Water quality

Some coating companies require that the dripping water must not exceed a maximum conductivity of 2 µS/cm. A demineralizer can normally produce a water quality of 5-20 μS/cm. With counter-current regeneration it can be as low as 1-5 μS/cm.

Prevent bacteria

Microbial growth can cause mechanical impurities and hereby contaminate vital elements in the surface treatment system and the coating quality. This can be avoided by continuously circulating the rinse water through a UV-disinfection unit that efficiently kills 99,9 % of microorganisms.

Extended bath lifetime

Continuously recirculating each bath through a bag filter retains mechanical impurities, metal shavings and deposits. This reduces how often the baths must be discharged. Filter bags are available in a wide range of variations, including special types with activated carbon fibers for removal of organics.

All-in-one reverse osmosis unit with pre-treatment

The all-in-one CU:RO compact unit is an excellent make-up water solution that provides softening and reverse osmosis with only a small footprint and easy installation.

Water treatment designed for the surface treatment industry

We have collected all you need to know about optimum water treatment for surface treatment. Think water first if you want quality products - every time!

See references from the surface pretreatment industry

How can we help?

Our team of specialists are ready to answer your questions about pure water treatment solutions.