Membrane degasser

Membrane degassing units (MDU) provide an efficient, compact, and maintenance-free technology to remove carbon dioxide and oxygen from water without any chemical treatment. Membrane degassing is a standard technology in industrial applications such as boiler feedwater, power generation and pharmaceuticals.

Removal of carbon dioxide and oxygen can prevent corrosion on boilers and piping to protect capital investment, extend life time of equipment, and reduce operating costs. Removing these gases can also improve the process efficiency, e.g. for EDI performance.

Advantages of membrane degassing unit

How to remove gases from water

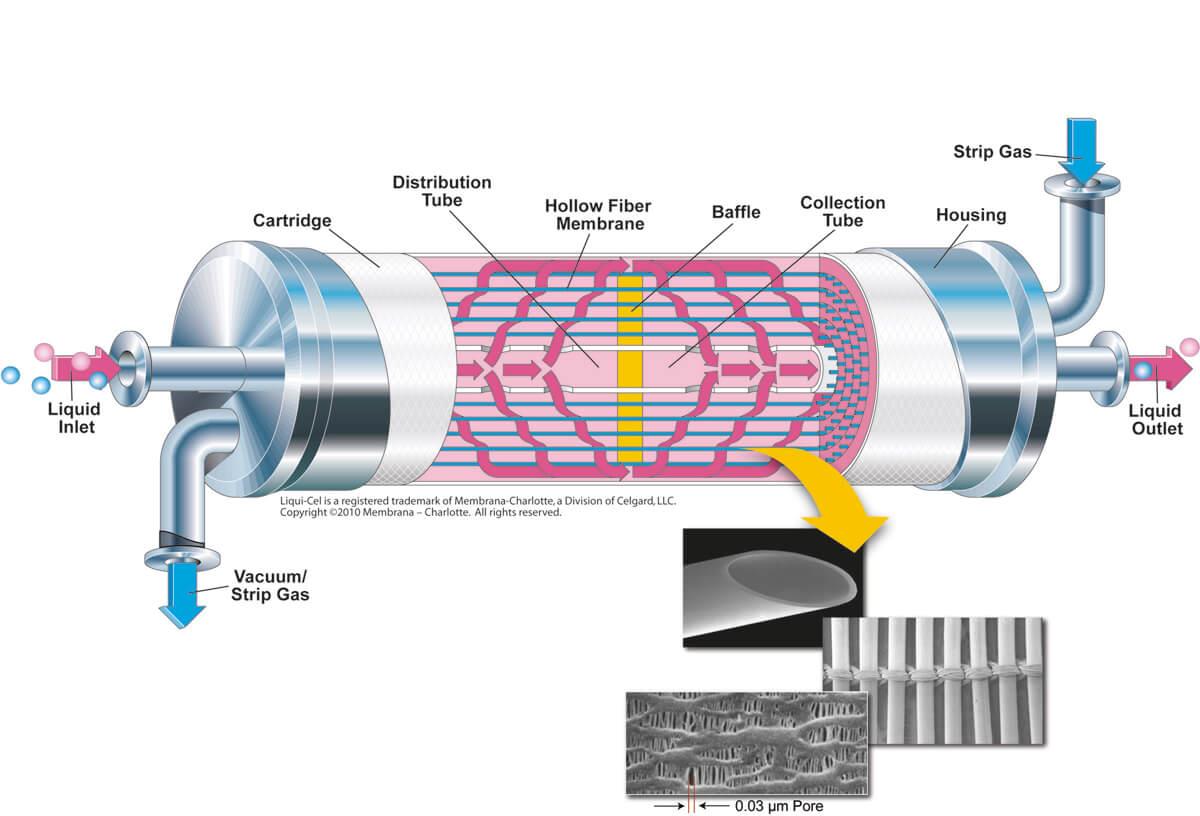

The membrane degassing unit uses a microporous hollow fibre membrane to remove gases from water. The hollow fibre is knitted into an array and wrapped around a center tube inside the housing.

During operation, water flows over the outside of the hollow fibres while a vacuum, strip gas, or both in combination, is applied to the inside of the fibres. Because the membrane is hydrophobic, it allows direct contact between gas and water without dispersion.

Applying a higher pressure to the water stream relative to the gas stream creates the driving force for dissolved gas in the water to pass through the membrane pores. The gas is then carried away by a vacuum pump and/or sweep gas.

Membrane degassing units

CO2 removal

Removing CO2 after the reverse osmosis (RO) unit and before the EDI unit (or mixed bed) reduces chemical usage and increases EDI performance. Less CO2 loading improves silica removal as well. The goal is to reduce CO2 content before EDI to less than 5 ppm. Operation mode is air sweep.

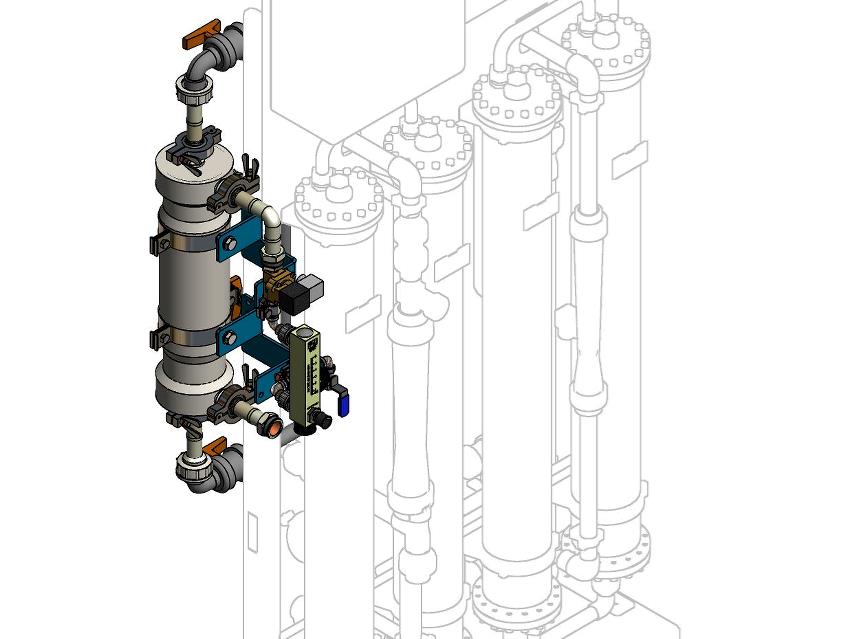

Add-on kit

Available as standard add-on kits prepared for reverse osmosis units from EUROWATER. Data sheets are available on request.

Individual solution

Can also be supplied separately to be mounted on existing RO units on-site.

Frame-mounted

Membrane degassing unit can also be an integrated part of a package solution with several technologies - frame-mounted and ready for use.

O2 removal

To prevent corrosion and avoid use of chemicals.

Operation mode is vacuum pump with nitrogen as sweep gas.

District heating

By removing the oxygen from the district heating water, you prevent corrosion in your installations and distribution network.

Boiler feedwater

Membrane degassing unit for removal of oxygen to less than 20ppb according to EN12952-12. A complete frame-mounted solution of stainless steel AISI 316.

Purified water

The application is removal of oxygen in cold water loop. The MDU unit is designed for hot Clean-In-Place (CIP) sanitization, which is a requirement for high-purity water (HPW) for United States Pharmacopeia (USP) and European Pharmacopoeia (Ph. Eur.).

Membrane degassing prevents corrosion

Spend 2 min. in company with Lars Jørgen Dam, Head of production at Skanderborg-Hørning District Heating and learn the effect of correct water treatment.

Recommendations

Water treatment & corrosion prevention

The Danish District Heating Association has published its recommendations for correct water treatment to increase life cycles of key assets such as boilers, valves, fittings, installations, and underground piping.

See references with membrane degassing unit

Get the optimum solution

Selection of unit depends on application, water quality, and water consumption. We are at your service to ensure the optimum solution based on our combined know-how. Fill in the form and let us get back to you.