UV disinfection systems

UV light can efficiently reduce microbiological growth in water. UV radiation with a wavelength of 254 nanometers kills bacteria, viruses, algae, and fungi by destroying the DNA of the microorganisms. Disinfection with UV light can be used for nearly all water types without leaving by-products or affecting the taste and quality of the water.

Cooperation with Wedeco

The UV systems are developed and produced by German Wedeco, which is one of the world's leading manufacturers of high-quality UV disinfection systems. We have cooperated with Wedeco since 1995 and built up a great expertise in UV for water treatment solutions.

Why choose Wedeco UV + EUROWATER

Low-pressure UV lamps - an energy efficient solution

With low-pressure UV lamps, excellent energy efficiency is achieved under all operating conditions, which also provides you with several operating benefits.

- No formation of by-products

- No build up of resistance

- No use of chlorine or other chemical disinfectants

- No danger of overdosing

- Short start-up time

- No cooling before restarting

- No staining of quartz tubes

UV as part of your operation or contingency plan

UV disinfection provides maximum operational reliability so the supply of water in the right quality can be maintained. The UV plant can be in permanent operation or commissioned periodically.

Permanent operation

Fixed system

UV systems can prevent any microbiological contamination from having effect on water quality or water supply. As a preventive solution, the plant will be in permanent operation as a hygiene barrier.

Periodic use

Fixed system

In the events of operational maintenance of the water treatment plant such as cleaning, installation of plants or filling of filter media, the UV system is put into operation to maintain security of water supply.

Urgent use

Mobile system

In case of immediate microbiological contamination of water supply, temporary application of UV can sustain the operation. At EUROWATER, we offer rental of UV systems with fast delivery and easy start-up.

Certified UV systems

We offer both certified and non-certified UV systems.

For the certified, it is documented by test that the required minimum dose is achieved. This ensures a high level of operational reliability and the best documentation in relation to authorities and consumers.

In some countries the use of UV systems requires approval from the authorities. Please contact your local EUROWATER office to learn more.

German

certification

Recertification every 5 years

Documents that the product meets the strict requirements of the German market. The standard is also widely used in the rest of European countries.

Austrian

certification

Recertification every 3 years

Standard developed for the Austrian market. The standard also applies in other countries, but to a lesser extent.

United States

Validation Protocol

Documented by 3rd party using "Letter of validation".

Standard developed for the US market and issued by the US EPA. The standard is globally recognized, and is often used in Europe on larger plants.

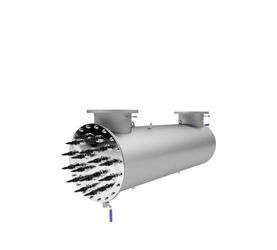

Product overview

The product range comprises several systems for disinfection of both drinking water and process water. Flow rates of standard are up to 6.000 m³/h. and the systems come with standard documentation for easy installation, operation, and maintenance.

System design

The UV systems uses Wedeco Ecoray® high-performance, low- pressure UV lamps with increased energy efficiency. Selected systems are equipped with OptiDose control which ensures that the energy level adapts to the current flow, conserving up to 50 % energy.

Automatic wiper system (optional) prevents the formation of organic and inorganic deposits on the protective quartz tubes. All sensor signals are available the standardized and user-friendly Wedeco EcoTouch controller. SCADA connectivity is possible with network / bus communication.

Contact your local sales and service office for more information, data sheets or instructions.

Flow from 1-6000 m3/h*

| Application: | Drinking water Process water Food Aquaculture |

| Product type: | Spektron e, large |

| Lamp type: | Low pressure |

| Operating temperature: | 5-60 oC |

| Certifications: | DVGM UVDGM ÖNORM |

| Control board: | Painted steel or stainless IP54 |

Flow from 1-18 m3/h*

| Application: | Drinking water Process water Food |

| Product type: | Spektron e, small |

| Lamp type: | Low pressure |

| Operating temperature: | 5-60 oC |

| Certifications: | DVGW ÖNORM |

| Control board: | Painted steel or stainless IP65 |

Flow from 1-150 m3/h*

| Application: | Drinking water Process water Food Pharma |

| Product type: | Spektron industrial |

| Lamp type: | Low pressure |

| Operating temperature: | 5-60 oC |

| Certifications: | Based on DVGW |

| Control board: | Stainless steel IP65 |

Flow from 1-100 m3/h**

| Application: | Drinking water Process water Food Pharma |

| Product type: | ME |

| Lamp type: | Low pressure |

| Operating temperature: | 0-60 oC |

| Certification: | Upon request |

| Control board: | Stainless steel IP54 |

Flow from 1-2400 m3/h*

| Application: | Drinking water Process water |

| Product type: | BX |

| Lamp type: | Low pressure |

| Operating temperature: | 0-60 oC |

| Certification: | UVDGM |

| Control board: | Painted steel IP54 |

Flow from 15-4100 m3/h*

| Application: | Drinking water Process water Aquaculture Ballast water |

| Product type: | Quadron |

| Lamp type: | Medium pressure |

| Operating temperature: | 5-60 oC |

| Certifications: | DVGW UVDGM |

| Control board: | Painted steel IP44/IP54 |

Flow from 1-11 m3/h*

| Application: | Drinking water Process water |

| Product type: | Aquada |

| Lamp type: | Low pressure |

| Operating temperature: | 0-35 oC |

| Certification: | Upon request |

| Control board: | Plastic IP23 |

Flow from 1-829 m3/h*

| Application: | Aquaculture Seawater |

| Product type: | Acton |

| Lamp type: | Low pressure |

| Operating temperature: | 5-35 oC |

| Certifications: | In progress |

| Control board: | Painted steel IP54 |

* at 98% UV transmittance (UVT)

** at 86 % UV transmittance (UVT)

Option

Frame-mounted

All UV systems can be delivered frame-mounted - ready for use!

The plant is complete with internal pipes and electrical connections for efficient installation on-site.

Thus, a frame-mounted solution requires fewer man-hours during installation. Contact us to hear more.

Option

Automatic wiper system

Wedeco's wiper system is fully automatic and chemical-free. The automatic wiper system prevents the formation of both organic and inorganic deposits on the protective quartz tubes.

As a result, the continual manual cleaning using chemical cleaning agents will hardly be required.

Operation of the wiper system is independent of whether the UV system is in standby or in operation. The system has built-in fault monitoring and can be retrofitted to existing Wedeco UV systems.

Option

OptiDetect® - quartz sleeve breakage detection

OptiDetect® is a patented detection system which in less than 1 sec. notifies you and activates a pressure switch if cracks or breaks occur inside the UV reactor.

The quarts sleeves is monitored by a separate control loop independent from the UV system’s electrical cabinet. This allows for the reactor to be completely shut down or for maintenance work to be done on the electrical cabinets, and still keep the system protected.

Control with EcoTouch screen

All UV systems are equipped the user-friendly WEDECO EcoTouch screen. It unifies all sensor signals and provides easy access to troubleshooting and information about the condition of the system.

The control is prepared for connection to SCADA systems with bus/network communication. By default, communication cards can be selected via Modbus TCP, Profibus DP and Ethernet IP.

Rent a UV disinfection system

Do you struggle with bacteriological contamination?

Rent a UV mobile water treatment system from EUROWATER.

See references with UV disinfection systems

Get the optimum solution

Selection of unit depends on application, water quality, and water consumption. We are at your service to ensure the optimum solution based on our combined know-how. Fill in the form and let us get back to you.