Frame-mounted water treatment plants - ready for use

A water treatment solution consists of several treatment steps, e.g. filtration, softening, and demineralization - all controlled from a central control cabinet. As standard, these units must be connected on-site.

With a frame-mounted water treatment plant, the units are assembled and tested off-site. This makes the plant ready for use when supplied, which financially can be an advantage, also in relation to the reduced amount of time used for deployment.

Why choose a frame-mounted water treatment plant

Complete water treatment system for manufacturer of brandy

When installation time and product quality have top priority, a factory-built solution offers many advantages. A Romanian manufacturer of spirits can attest to this with their complete water treatment solution.

“The installation time was very short. From placing the two frames on site, it only took two days to make piping and electrical connections between the frames and tying it into the existing process. The plant produced high water quality from the start.”

Florian Radu, Managing Director of Hydro-X

local EUROWATER distributor in Romania

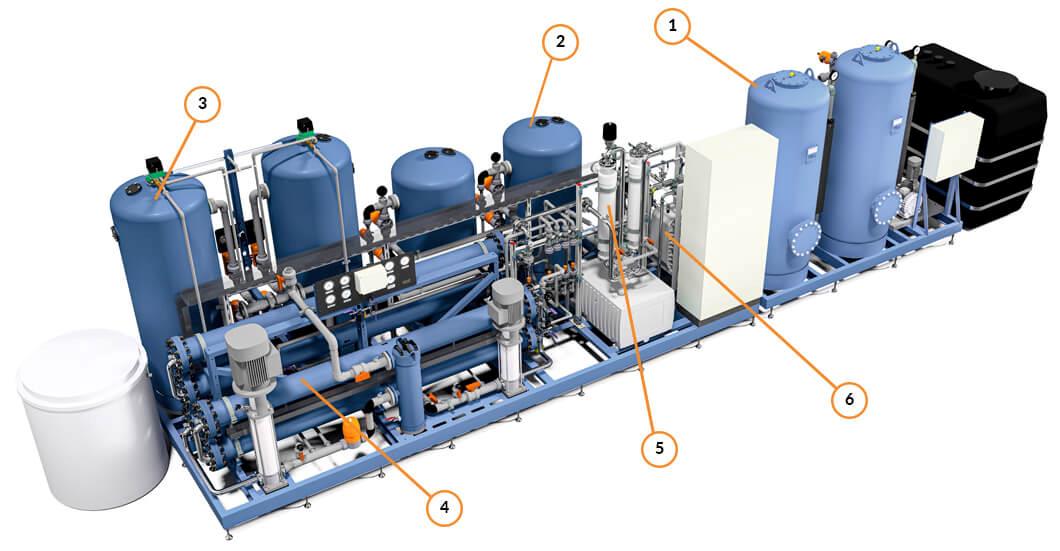

1. Filtration

Removal of iron and manganese from groundwater in automatic pressure filters.

2. Activated carbon filter

Activated carbon filters remove colour, taste and odour from the water and serve as an extra safety precaution.

3. Softening

Softening unit for reducing the hardness in the water and preventing calcium deposits in the subsequent membrane filtration unit.

4. Reverse osmosis

Two reverse osmosis units (double-pass RO) are connected in series so the second unit treats the permeate from the first unit.

5. Membrane degassing

The membrane degassing unit (MDU) provides an efficient and chemical-free technology for removing CO2 from the RO permeate.

6. EDI

The EDI unit is used after the RO system for polishing of demineralized water to obtain low levels of conductivity.

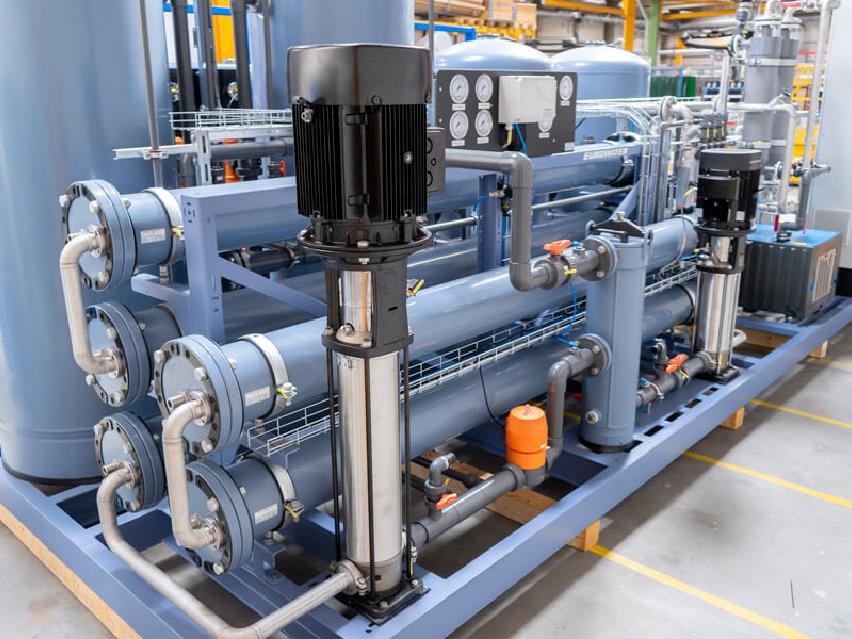

Have a look at a frame-mounted water treatment plant

Examples of frame-mounted water treatment plants

Plug-and-play water treatment plant for biomass steam boiler

The water treatment plant is designed for producing 2 x 3.25 m³/h of ultrapure water as make-up water for a high-pressure steam boiler. The frame-mounted water treatment plant consists of:

- water pre-heater

- duplex softener

- 2 x reverse osmosis

- 2 x EDI

- Central PLC control

Frame-mounted water treatment plant for turbine water

This complete water treatment plant is made for a 90 MW power plant in Africa. The plant is designed for producing ultrapure water for a turbine, cooling water and water for firefighting. The plant consists of:

- Filtration

- Activated carbon filter

- UV-disinfection

- Dosing of antiscalant

- Mechanical filtration

- Double-pass reverse osmosis

- EDI

- Central PLC control

Turnkey frame-mounted solution for hospital

A complete frame-mounted solution for one of the largest hospitals in Denmark. The plant consists of a softening unit for continuous supply of softened water and a reverse osmosis unit for supply of demineralized water. The plant consists of:

- Softening unit

- Reverse osmosis unit, RO-PLUS

- Water reservoir

- UV disinfection unit

- Central PLC control

Learn more about frame-mounted water treatment plants

We have constructed many different custom-made frame-mounted water treatment plants adapted to specific demands and wishes. Please contact us for further information and to hear your options.