Thermal deaerator

A thermal deaerator is used for reducing the oxygen content of steam boiler feedwater. Without proper treatment, feedwater for steam boilers typically has a high oxygen content of 8-10 mg/l, which causes critical corrosion in the system.

Theory of operation

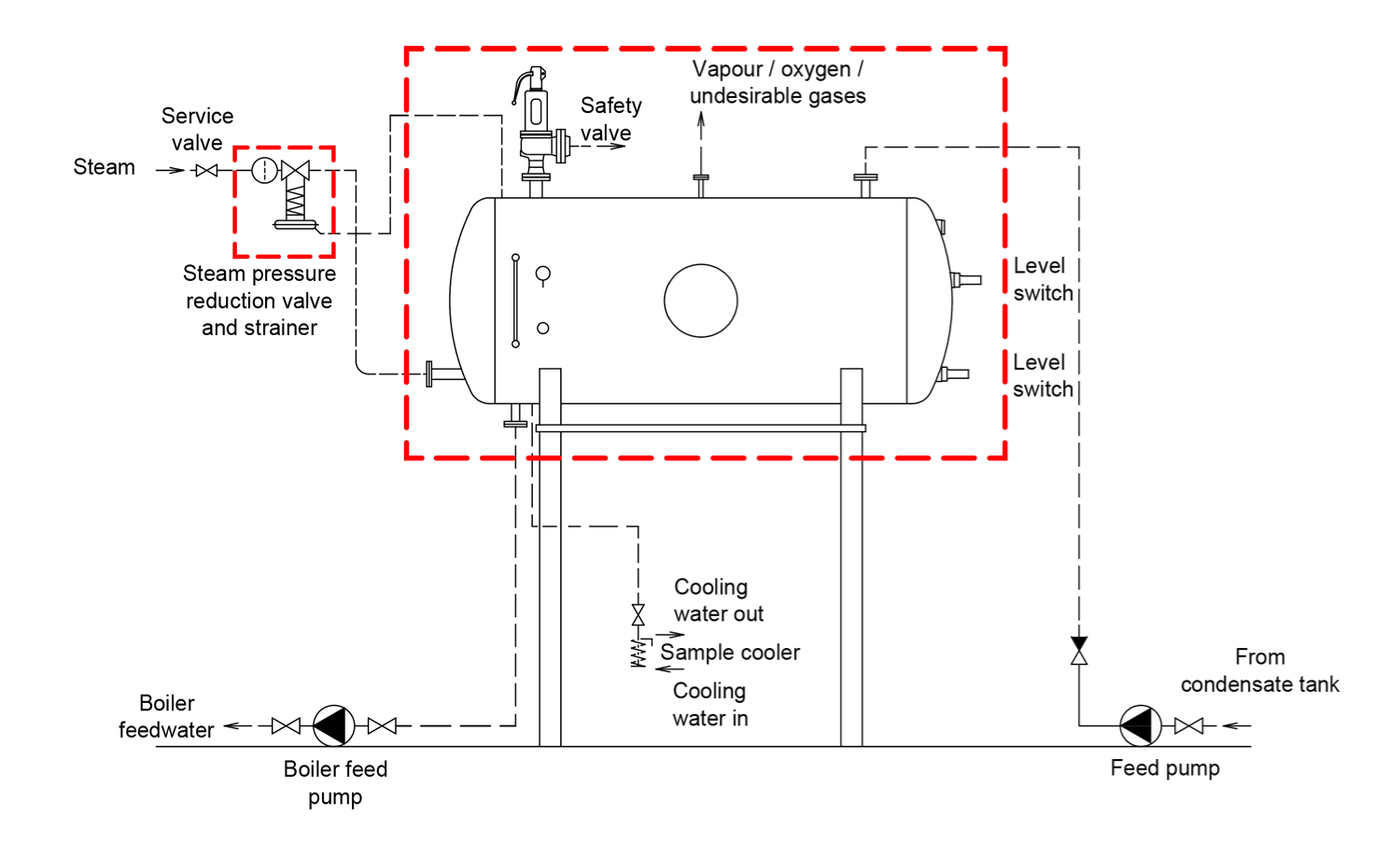

The condensate and the make-up water are mixed so that a temperature of 60-70°C is reached before conducted to the top of the deaerator. In the top of the deaerator the water is vaporized, so the gases can escape the layer that surrounds every single water molecule.

Steam is conducted to the bottom of the deaerator through a steam pressure reducing valve and steam injectors create the necessary turbulence in the water for an efficient deaeration. The excess gases are allowed to escape through a vent with a restriction.

Plant design

A thermal deaerator from EUROWATER is available in 12 units with flow rates up to 40 m3/h and tank volume from 1,450 litres to 23,150 litres. The deaerator tank is made of steel with end-caps for higher pressure tolerance and constructed according to CE regulations.

The thermal deaerator works at an excess pressure of 0.2 bar, corresponding to a boiling point of 104oC.

All units come with standard documentation for easy installation, operation, and maintenance.

Contact your local sales and service office for more information, data sheets or instructions.

Thermal deaerator

The spray-type consists of a horizontal cylindrical vessel which serves as both the deaeration section, and a storage tank for boiler feedwater.

| Product type: | TA |

| Water quality: | 50 ppb O2 |

| Water inlet: | Directly in tank |

| Holding tank: | ~20 min. |

| Switch in end-cap: | 2 levels Operational + dry-run |

| Visual: | Level glass |

| Steam distribution: | Pipe with nozzles |

| Outside coating: | Yes |

| Inside coating: | Yes |

Thermal deaerator with dome

The spray & tray-type, or also called cascade-type, includes a vertical dome deaeration section mounted on top of a horizontal cylindrical vessel which serves as the deaerated boiler feedwater storage tank.

| Product type: | TD |

| Water quality: | 20 ppb O2 |

| Water inlet: | In top of dome |

| Holding tank: | ~30 min. |

| Switch in end-cap: | 1 level Dry-run |

| Visual: | Level glass with level switches |

| Steam distribution: | Pipe with holes |

| Outside coating: | Yes |

| Inside coating: | No |

| Dome: | AISI 304L |

Premium design and reliable operation

Thermal deaerator with dome.

- Dome with trays

Ensures a very reliable and stable operation and not sensitive to changes in flowrate. - One steam injection

Steam injection is handled from the bottom of the holding tank, which makes it easy to control and cause all the steam to pass through the dome. - Excellent water quality

Oxygen level less than 20 ppb.

Equipment

Thermal deaerator with or without dome suitable for steam boilers supplied complete with fittings, i.e. steam pressure reducing valve and safety valve, level control, water level indicator, thermometer, and pressure gauge.

| Included in delivery | Not included |

| Thermal deaerator | Connecting pipe system |

| Steam pressure reduction valve | Support stand |

| Safety valve | Pumps |

| Counter-mating flanges | Service valve |

Option

Insulate to prevent heat loss

Prevent the condensation of steam and loss of heat by insulating the deaerator, and in general all installations in contact with hot water. A deaerator type TA from EUROWATER can be supplied insulated with 100 mm of mineral wool covered by aluminium plate.

Option

Sample cooler - monitor the work of the deaerator

Use a sample cooler to monitor the function of the boiler or the thermal deaerator. A sample cooler ensures efficient cooling according to the counter-current principle and no contamination of the sample.

Download leaflet to read more about function and benefits.

Get the optimum solution

Selection of unit depends on application, water quality, and water consumption. We are at your service to ensure the optimum solution based on our combined know-how. Fill in the form and let us get back to you.