Water and energy saving at Danish hospital

Published: 06 February 2020 | Contact

Thousands of patients are treated at Odense University Hospital (OUH) in Denmark every day. It is OUH's ambition to ensure that every patient receives highly qualified treatment and that they feel well treated in terms of nursing and care. To meet this ambition, access to water of the right quality and in the right place is an important factor.

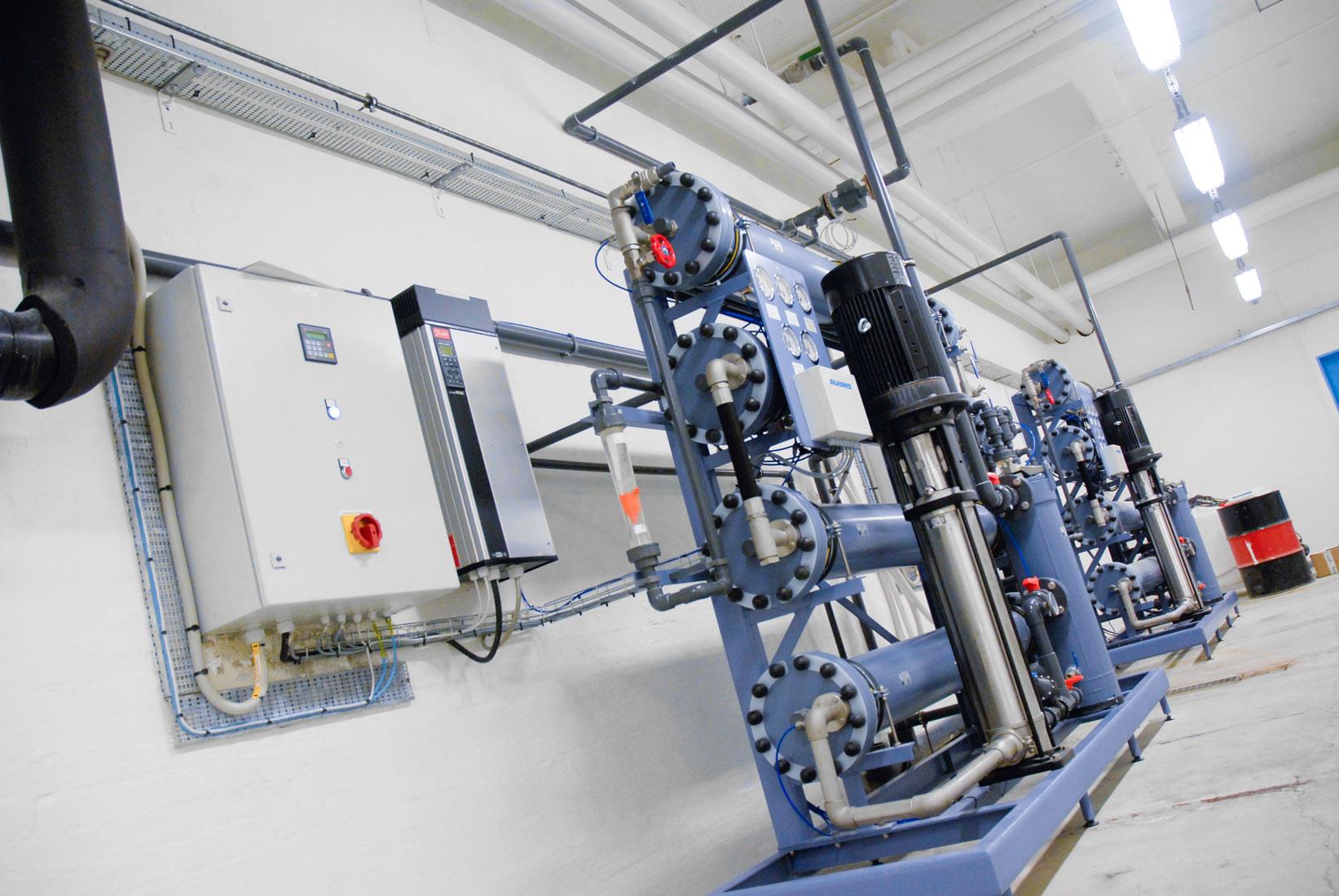

When OUH was to have a new water treatment plant, the hospital wanted a robust solution focusing on operational safety and economy. To meet these requirements, Silhorko-Eurowater needed to utilize new and energy-efficient technologies to minimize water and energy consumption.

The result was a water treatment plant with minimum consumption of water, salt, and electricity.

Softening plant

OUH chose a softening plant of the type STFA comprising two tanks with ion exchange media. The softening plant has a total treatment capacity of 50 m³/h and is designed with a distributor section ensuring a uniform and even flow, thereby fully utilizing the capacity (total volume of the filter media).

The regeneration of the softening plant represents a large part of the total operating costs. Various special features minimizing the consumption of water and salt for regeneration:

- Monitoring of the regeneration water quality

- Reuse of regeneration water from the various regeneration phases to the greatest possible extent

- Plant designed to use exactly the amount of salt needed regardless of ambient temperature

Part of the softened water is used as process water in the washing machines, dishwashers, and bedpan washers. The remaining volume is processed in three RO systems.

Water and energy saving reverse osmosis system

OUH chose three RO systems of the type RO-PLUS. This type is characterized by having a high recovery of up to 90 %. In comparison, most other types of RO systems have a recovery of about 75 %.

RO-PLUS is designed for higher recovery without compromising on water quality or reliability of operation. In theory it may sound simple to achieve higher recovery, but in practice it can be problematic if you do not have the right experience and know-how. Each RO system is designed for a performance of 7 m³/h.

The high recovery not only results in significant savings of water consumption, but also of energy consumption. Energy consumption per m³ is reduced by utilizing a larger quantity of the inlet water.

The demineralized water is used for steam boilers, autoclaves and in the laboratories.

Water treatment system with hygiene barrier

At OUH, there are large fluctuations in water consumption during the day. To obtain an optimum production flow, the treated water is stored in a buffer tank. This reduces both electricity, water and salt consumption significantly.

To avoid bacteriological contamination, the water from the buffer tank is continuously recycled through a UV system and a reverse osmosis system. UV light disinfection effectively eliminates all microbiological growth in the water by destroying the microorganisms' DNA, i.e. bacteria, viruses, algae, and fungi. The RO membranes remove all organic matter and thus also act as a hygiene barrier.

Compared with the old water treatment plant, the new water treatment plant at OUH achieved such large operating savings that the payback period was approximately one year.