Case

Water treatment for modern dairy technology

Reliability, energy efficiency and sustainability were decisive factors when BIAGR dairy in Ukraine decided on a complete turn-key water treatment solution. The project included design, equipment supply, installation and commissioning.

To support the market introduction of new dairy products, BIAGR dairy decided that a complete reconstruction and implementation of new diary technology - including the water supply system – was a necessary step. Reliability, energy efficiency and sustainability were decisive factors, so it was only natural to decide on Silhorko-Eurowater as supplier. Their solutions are successfully operated in dairies all over the world and with references in Ukraine by PepsiCo (Vimm-Bill-Dann), Danone and RUD.

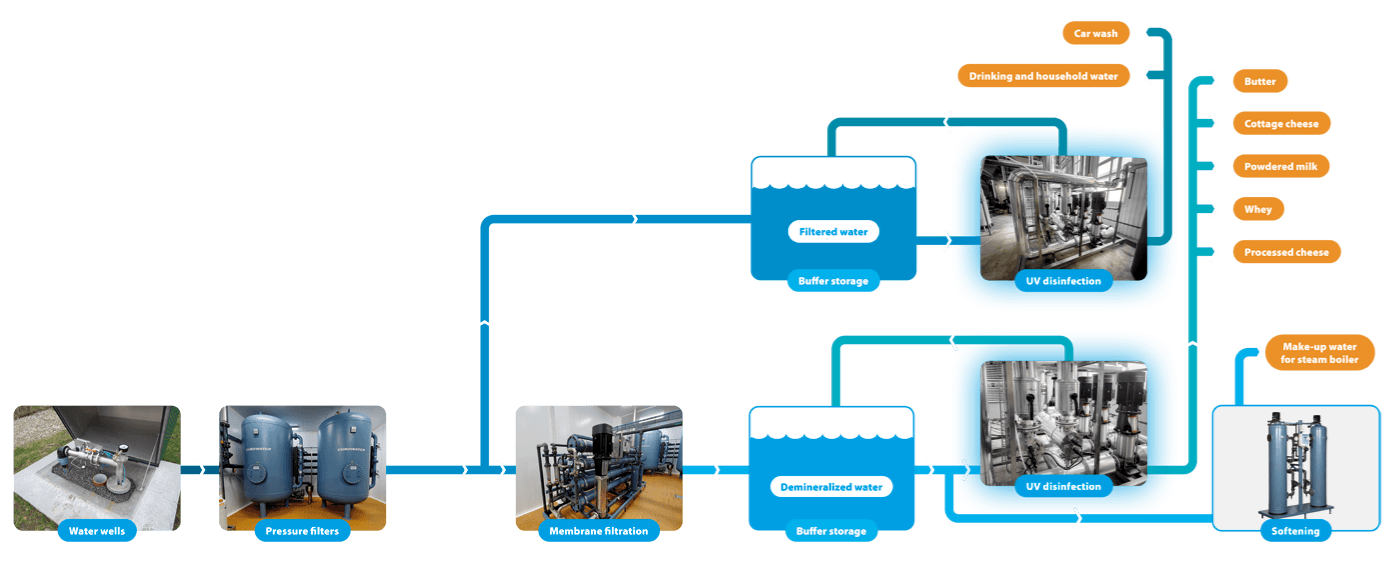

The main task was to provide a complete solution: From pumping raw water from six water wells, then treating it to a few specific water qualities required by the different applications, to distribution to every point of consumption with the appropriate flow and pressure.

3D virtual tour

Take a 3D virtual tour at the new water treatment installation and get more information on the units and treatment process.

Realization of the solution

Dimensioning was necessary to make a 3D design of the complete water supply system, including calculations of all hydraulic and technological parameters.

All wells were equipped with Grundfos SP pumps operated by CUE frequency converters. These advanced pumps eliminate the need for intermediate holding tanks, thereby greatly reducing the microbiological risks caused by standing water.

Since the iron and manganese contents in the raw water are above the drinking water limits, two pressure filters (type EUROWATER TFB35) were installed with an aeration system for controlling proper oxidation. The pressure filters were followed by two membrane filtration units (type EUROWATER C3-21) - producing a total of 50 m³ of demineralized water per hour.

The treated water is collected in large storage tanks:

- Filtered water for drinking and domestic purposes.

- Demineralized water for a wide range of processes, such as CIP, rinse, push-out, and cooling to produce butter, cottage cheese, powder milk, whey, and processed cheese.

Make-up water for the steam boiler is produced by removing residual hardness from the demineralized water, using ion exchange technology, which ensures no scales or corrosion and good steam quality.

All the water is distributed via Grundfos pumps type CRNE. UV disinfection units (type Wedeco BXe) with a total capacity of 300 m3/h, serve as microbiological barriers, including a recirculation feature for eliminating the risks associated with standing water.

BIAGR: We needed a 100 % water solution

“We wanted a contractor with expertise in water for dairies and we were searching for a supplier active in the local market as well as the European market. The supplier should have the capacity to take responsibility for the whole water process, beginning from wells and ending with the last valve before consumption. In 2018, we visited the Silhorko-Eurowater HQ in Denmark and a few dairy facilities with their water solutions. We were impressed by how daily business were organized, their values and customer orientation."

CEO, Roman Kovalenko

The water treatment system has been running for more than half a year. It exhibits much lower OPEX and higher efficiency of the technological processes than the old system. One of the most significant benefits is the highest dairy product quality possible!

This case is featured in the latest issue of Danish Dairy & Food Industry 2021 (Opening new tap). Here you can also read other relevant topics for the dairy and food industry.

Facts

About BIAGR dairy

BIAGR dairy is located in Poltava region of Ukraine and was founded in 1980. The dairy products are distributed to more than 70 countries world wide. With the new water treatment solution they are realizing their social mission by supplying drinking water not only water for own production, but also the local kindergarten and village hall.

Read more about BIAGR

bilotserkivske.com

Units in water supply system

- Grundfos SP pumps

- EUROWATER pressure filters type TFB 35

- EUROWATER reverse osmosis units type RO C3-21

- Grundfos CRNE distribution pumps

- Wedeco UV units

- EUROWATER ion exchange softening unit type SMH 902-F