Technieken

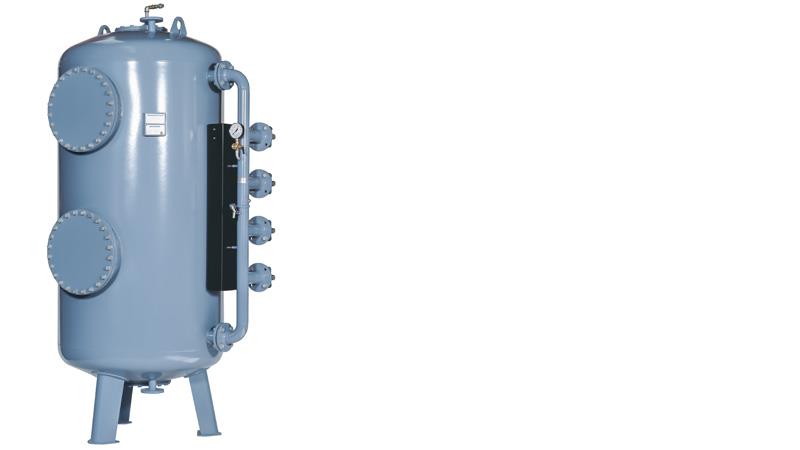

Ionenwisseling

Ontharders | Demineralisatie | Dealkalisatie | Mengbed | SILEX | EUREX

Membraan filtratie

Omgekeerde osmose units | Nanofiltratie units | Compact units CU:RO

Besturing en automatisering

Automatiseer uw waterzuiveringsinstallatie met een besturings- en automatiseringssysteem. Standaard hardware, flexibele software, ons ontwerp.

Zoek product op onzuiverheid

Kies de onzuiverheid die u uit het water wilt verwijderen.

Infectanten

Algen | Bacteriën | Chlooramine | Chloordioxide | Vrij chloor | Schimmels | Virussen

Gassen

Hardheid

Calcium | Kalkaanslag | Magnesium | Silica

Metalen

Arseen | Zware metalen | Ijzer | Mangaan | Natrium

Organische stoffen

Waterkwaliteit

Van drinkwater tot ultrapuur water. Kies de waterkwaliteit die u nodig heeft en bekijk productoplossingen.

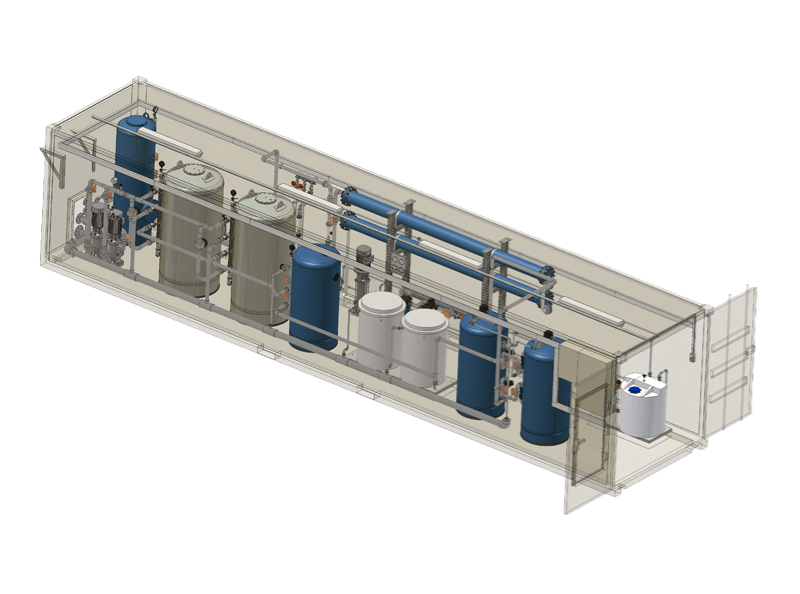

Kant en klare waterbehandelingsoplossingen

Volledige oplossing voor waterbehandeling. In de fabriek gebouwd, getest en klaar voor gebruik!

Op zoek naar een overzicht?

Klik hier voor een volledige lijst van alle waterbehandelingsinstallaties.

Huur een mobiele waterbehandelingsinstallatie

Heeft u tijdelijk drinkwater, gedesinfecteerd, onthard of gedemineraliseerd water nodig?

Wij bieden een breed scala aan mobiele waterbehandelingsinstallaties.

Zie geselecteerde waterbehandelingsoplossingen

Hoe kunnen we u van dienst zijn?

Ons team van specialisten staat klaar om uw vragen over puur waterbehandelingsoplossingen te beantwoorden.