SILEX with vessel

With SILEX you have unlimited access to demineralized water of high quality - and you avoid purchase, handling and disposal of plastic bottles with water.

This SILEX unit is a vessel with ion exchangers. Demineralized water is produced when water passes through the vessel. When the capacity of the resin is exhausted, the vessel is sent for regeneration.

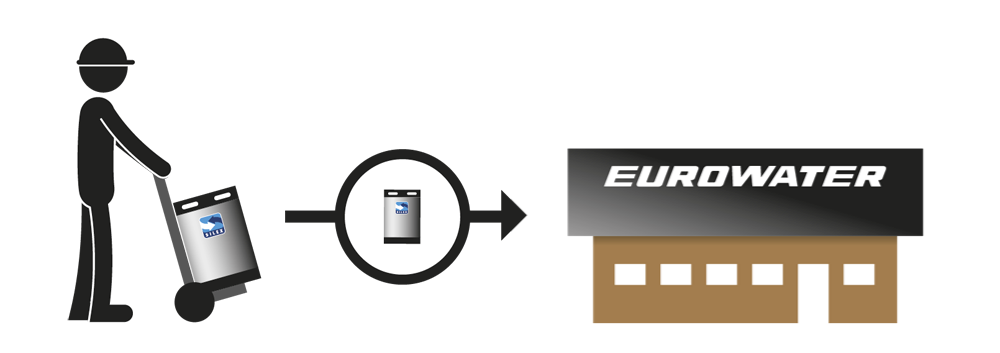

We handle the regeneration

The regeneration is handled at the EUROWATER factory. This way you avoid storage and handling of chemicals. You only have to replace the SILEX vessel with a recharged vessel and you are good to go.

Capacity

The SILEX with vessel is able to supply up to 420 litres of demineralized water per hour. The capacity depends on the quality of the inlet water. At an inlet water total dissolved solids of for example 20 °dH, the capacity is 1,135 litres. Should you need higher flow rates or greater capacity, we are also able to offer you this.

Why choose a SILEX with vessel system

Easy regeneration

When the conductivity is too high for the application, or the ion exchangers are exhausted, the vessel must be replaced in a few easy steps:

- Empty the vessel for water

- Return the exhausted vessel to your local EUROWATER department for regeneration

- Insert a new regenerated vessel

- Open valves and get access to demineralized water

To ensure a continuous supply of demineralized water, we recommend having an extra vessel as backup.

Option

Operating unit for easy operation

To ensure low transport weight, for easy and safe handling, the vessel must be drained for water before regeneration. An operating unit makes it easy to drain the vessel before regeneration. The operating unit also ensures easy quality rinse and connection/disconnection of the vessel.

Product overview

SILEX with vessel system consist of two units.

Download leaflet on SILEX 11 & 21 to read more about the vessel system and options.

SILEX 11

| Max. flow rate: | 240 l/h |

| Cartridge capacity: | 1300 l at 10 °GH |

| Conductivity: | <0.2 μS/cm |

| Transport weight: | 15 kg. |

| Inlet / outlet connection: | dia. 10 mm hose |

| Measurement: | Diameter: 23,7 cm Height: 40 cm |

SILEX 21

| Max. flow rate: | 420 l/h |

| Cartridge capacity: | 2270 l at 10 °GH |

| Conductivity: | <0.2 μS/cm |

| Transport weight: | 24 kg. |

| Inlet / outlet connection: | dia. 10 mm hose |

| Measurement: | Diameter: 23,7 cm Height: 60 cm |

Demineralized water for physicians

Equipment used for examination can be sterilized in an autoclave. Demineralized water is required for proper function and a hygienic result.

Get high quality water for tests

Demineralized water is a necessary tool for laboratory applications and testing. The water is almost free of all dissolved minerals and the conductivity can be less than 0.2 µS/cm.

Demineralized water for schools

When teaching chemistry, many experiments involve using demineralized water. SILEX gives easy access to demineralized water - without chemical handling by the personnel.

Get easy access to demineralized water

Provide your own demineralized water and let us handle the regeneration. Our experienced team of sales and service engineers are ready to get you started.